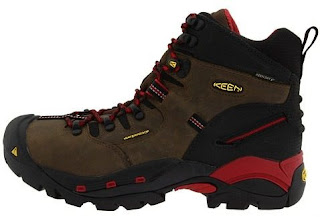

Security boots

Are the most common type of safety footwear. They must incorporate safety toes, usually steel, along with other safety features such as non-slip soles, puncture-resistant midsoles, and insulation against extreme heat and cold.

safety shoes

They also have safety tips, although they are usually made of composite materials. They are less robust than safety boots so they are more comfortable, but offer less protection. They are the most recommended option for people who need medium protection for much of the day.

Sports safety shoes

More casual and comfortable tennis. Most have composite safety tips. Although they offer less protection, they are ideal for activities that involve constant movement.

Wellingtons

Waterproof boots without laces, very useful as protection against water and mud. They are made of rubber or PVC. They may also have a safety tip.

Criteria for selecting the best safety footwear

safety tip

They are practically the element that make the boots, safety boots. They protect your feet from injury and are required in many jobs. When shopping, it's important to buy a pair that fits from the start, because these extra reinforcements make it difficult for the boots to adapt to your foot.

Shoe durability

When buying boots quality should be your priority. In this many times the brand does not matter. The important thing is the materials used, the quality of the sewing and the union between the sole and the body of the boot.

Waterproof

If your work environment is in humid conditions or if you live in a region where it rains a lot, you should look for boots made of materials suitable for these conditions. Leather ones are heavier and larger, while nylon ones are lighter and have additional protection against water.

boot insulation

The extra insulation is helpful in keeping your feet warm in a cold environment. But, you should only invest in this if you really need it.

Anti-slip shoes

Made of special rubber that prevents slipping on wet floors. Useful when the environment is slippery, used mostly in the food or manufacturing industry.

brands

When buying safety boots, the brand matters. It is best to go to the easy and buy boots from recognized and reliable brands. You should also be careful with imitations, as it is common for the most popular models of the big brands to have imitations.

shoe comfort

Many people believe that safety shoes are uncomfortable, when in reality safety shoes are designed to feel like any other. It is important that the boots are ergonomic to reduce fatigue at work.

Other functionalities of safety footwear that must be considered

- Electric resistance

- oil resistance

- traction soles

- ankle protection

- High resistance, heavy and hard insoles

- Thick materials around the foot

- antimicrobial insoles

- Anti-perforation insoles

Shoe safety toe

steel safety toe

|

| Source: Pronghorn |

Steel tips, in addition to being the standard material in the industry, are the most used. They are the cheapest option, but also the heaviest. They conduct cold or heat, so they should be avoided in jobs with extreme temperature conditions.

They also offer greater puncture protection than tips made of composite materials.

Composite Materials Safety Tip

|

| Source: Pronghorn |

Composite safety tips are metal-free, usually made from plastics, kevlar, and carbon fibers. They are lighter than steel toes, which makes them more comfortable. In addition, its electrical resistance is greater than that of steel spikes and it does not activate metal detectors.

They can also be used in any weather condition and are more heat-retaining in cold conditions. The problem with this material is that it is more expensive.

Aluminum safety tip

Metatarsal protection in footwear

What to look for in safety shoe soles

rubber sole

It is a very common material for the soles of this type of footwear. Rubber soles are abrasion resistant and slip resistant, vital features in many work environments. Usually each manufacturer uses their own style of rubber which gives their soles additional safety attributes.

Thermoplastic polyurethane (TPU) soles

The soles made of this material are durable, thin, light and resistant to abrasion. Also are non-slip, they provide a good grip to the floor and resist low temperatures.

EVA midsoles (foamy)

They are designed to disperse weight and provide stability. It is a material similar to foam (a foam) so it is light, flexible and cushions the steps. In addition, they have many desirable characteristics: they are resistant to water and corrosion, washable and recyclable.

Key elements of safety footwear production

The most important step in the manufacture of the boot is the union of the sole with the body of the boot. The duration of the boot depends largely on how this procedure is performed.

cemented mounting

It refers to how the sole is attached to the body of the boot. Usually cements or glues are used for this purpose. It is the cheapest and most common method of joining the sole, which is why boots made this way cost less. However, over time the union between the sole and the body of the boot weakens, so it must be replaced instead of trying to repair it.

Goodyear stitching

Common mistakes when buying safety footwear

- In general, safety footwear is designed for a specific use. But, they can look very similar, which causes confusion. It is easy youend up buying safety boots or shoes that are useless in the end. If you buy the wrong footwear, it will not last and worse, you will expose yourself to risks.

- Likewise, it is common choose the wrong size. It is not normal that at the end of the workday the feet are raw, tight or with blisters. In addition, shoes that are too tight can also contribute to the growth of calluses or ingrown nails. Not all sizes are the same between brands, as manufacturers carve their footwear according to certain specifications. If when you try on the boot it feels too tight look for a wider one.

- Buy cheap shoes ignoring the quality. C.Buying safety shoes to save money always turns out to be a bad investment.

- Not looking at safety standards. You need to know the standards relevant to your job. For example, in Mexico the NOM-113-STPS-2009.

- Prioritize style over safety. While the Producers prioritize safety, buyers are more interested in style.

Safety footwear care

- Taking care of footwear helps increase its useful life. Clean and polish the leather with special oils to keep it supple and waterproof.

- Store the footwear in clean and dry places to prevent odors and preserve the leather.

- Regularly check the boots for damage. Resistance to electric shock is reduced by wear.

Final tips for buying the best safety footwear

- Go prepared the day of purchase: wear the socks you normally wear to know how well the boot fits. If you are going to buy them online, look at the size guide to make sure they fit you well.

- Seek comfort: While protection is paramount, don't compromise on comfort. Nowadays, producers incorporate many elements designed for greater comfort, safety and hygiene, such as: antibacterial insoles, asymmetrical steel toes, additional padding, etc. Further: boots insoles buying guide

Sources

Safety footwear according to use (industry)

| Sector | desirable characteristics |

| Agriculture | (Rubber boots) Safety tip, non-slip and antistatic and waterproof |

| Construction | 200J safety toe, puncture resistant midsoles |

| Cold storage | Safety toe made of steel or composite materials, waterproof and with thermal protection |

| Foundries | Safety toe, metatarsal protection, quick release buckles |

| Forestry | Safety toe, grippy soles, puncture resistant midsoles |

| Health | Non-slip soles, easy to clean, comfortable sole |

| Chemical products | Chemical resistant, slip resistant footwear |

| Storage | Safety tip, antistatic, slip resistant, chemical resistant |